Flexibility

Flexibility“Historically most precise” semiconductor equipment x Tailor-made transport plan by charter flight. The moment a bond was born by eastern Malaysian City

Flexibility

Flexibility“Historically most precise” semiconductor equipment x Tailor-made transport plan by charter flight. The moment a bond was born by eastern Malaysian City

Not only Japan domestic, but also on a global scale, ANA Cargo transports the valued customers' important shipments to each country in the world. In addition to general cargo, transport of special commodities, such as delicate animals like horses or pandas, and highly sensitive and delicate semiconductor parts, is realized by its advanced transport handling skills or technologies.

ANA's international routes (passenger & freighter flights) possess an extensive network of total 44 airports in North America, Europe, Asia, and China (as of March 2025), aiming to deliver safety & reliability across the borders in the world, as well as to provide high Japan-quality services. It can be said that the strength or advantage of ANA Group is the high-level transport infrastructure.

ANA Cargo not only provides transport services to scheduled online destinations, but also to non-operated offline points, by arranging charter flights in response to the customers' requests.

In 2024 end, an extremely precise semiconductor equipment was transported to the eastern Malaysian City, by a charter flight. How could the semiconductor equipment, a delicate special cargo, safely delivered overcoming various obstacles or hurdles to transport to offline points?

The scenes behind the major mission, undertaken together by the airline, ANA, and the shipper, Nikon, and the cargo forwarder, "K" Line Logistics, connecting the 2 parties, shall be featured.

A team essential for the transport of "historically most precise machine" - semiconductor exposure equipment

The eastern Malaysian City, the destination of the transport, has the largest scaled domestic industrial park, and is a City attracting the worldwide attention as a new business hub. Currently, several domestic and overseas companies have moved into this City, while quite a few manufacturers relocating their production base. This semiconductor equipment transport mission was also based on such background.

The special cargo transported this time is a semiconductor exposure equipment, said by Nikon to be "historically the most precise machine". Circuit pattern data is burnt onto silicon plates called as "silicon wafers", producing semiconductors indispensable to manufacture automobiles and smartphones that support our daily lives.

Mr. Ryohei Itagaki, Logistics Department, Procurement and Logistics Sector, Production Technology Division, Nikon Corporation, adds the characteristics of this time's semiconductor exposure equipment as follows;

Mr. Ryohei Itagaki, Logistics Department, Procurement and Logistics Sector, Production Technology Division, Nikon Corporation

Mr. Itagaki: "Semiconductor exposure equipment is an extremely large and sensitive precision machine, measuring 3 meters in total length and weighing over 30 tons. Even a slightest shock may damage the internal parts, leading to a fatal situation. In addition, it is sensitive to temperature changes. If the performance of the equipment's lens changes depending on the outside temperature, or condensation occurs due to temperature differences, it can significantly impact the product's accuracy. Due to the nature of the cargo being best suitable for air transport, despite some concerns, but using ANA Cargo was decided, which has a proven track record of semiconductor exposure equipment transports."

So, ANA Cargo was chosen. There was a confidence to provide high service quality based on the past proven track record of transporting Nikon's semiconductors, as well as having such as the internal "Professional Unit", consisted of employees with outstanding handling skills in special cargo transports.

"When ANA was selected, I was determined to definitely make this transport a success" said Ryutaro Hamada, Tokyo Sales, International Cargo Sales Japan, ANA Cargo Ltd., in charge of international cargo sales activities, who was involved in this transport mission.

Mr. Ryutaro Hamada, Tokyo Sales, International Cargo Sales Japan, ANA Cargo Ltd.

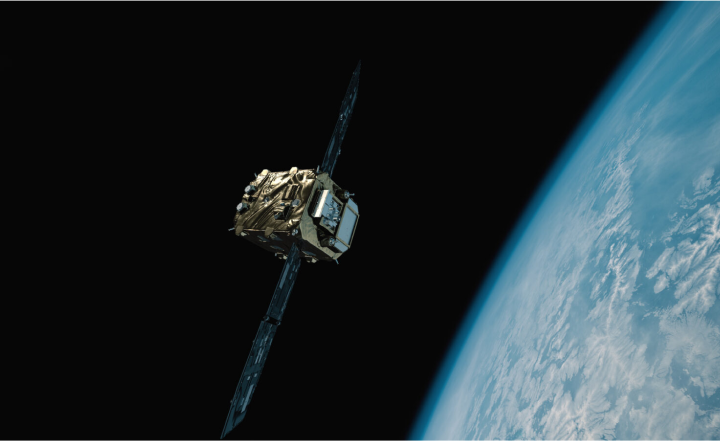

Mr. Hamada: "This time's charter flight arranged to eastern Malaysian City was the first time to operate for ANA. However, since we already had an experience to transport artificial satellite to an offline point, Aukland, New Zealand, in the past by a charter flight, it made us excited thinking 'the time has come to utilize the know-how accumulated by entire ANA'. To be well prepared for the transport, repeated communication was held with the forwarder, "K" Line Logistics."

A forwarder plays the role as a mediator or coordinator between the shipper and airline. "K" Line Logistics has the know-how in semiconductor transport, and also the network at the destination, eastern Malaysian City. Mr. Takateru Fukami, Semiconductor Sales Section, Project Cargo Department, "K" Line Logistics Ltd., referred to the collaboration with ANA Cargo as follows;

Takateru Fukami, Semiconductor Sales Section, Project Cargo Department, "K" Line Logistics, Ltd.

Mr. Fukami: "A forwarder is in a position to propose the transport methods, and make the arrangements in accordance with the customer's requests. When selecting an airline, we strongly recommended to Nikon saying 'ANA Cargo definitely is the right choice'. Not only did the conditions match, but also due to the trust we had for ANA's high transport quality or response ability at occurrence of unexpected incidents. As a forwarder, it was very reassuring to be able to say with confidence that the transport will be just fine."

Airlines, shippers, and forwarders. Despite there being various stakeholders involved in the air transport, this time's success owes to the close cooperation among the 3 parties.

Air transport for precision equipment with consideration for impact risks. We handle the transportation of semiconductor manufacturing equipment, medical devices, and more, equipped with ShockWatch and TiltWatch indicators.

PRIO SENSITIVE→

Process preparation for temperature control & full-loading. System establishment by 3 parties as 1 team

Various hurdles had to be overcome for the transport.

To operate a charter flight to an offline point, not only securing an aircraft but also various adjustments in regard to handling are required. The preparation period usually takes about 3 months, but for this time, the schedule was extremely tight limited within less than 2 months until the date of transport. By closely coordinating with the concerned teams of ANA Cargo, in charge of network or flight schedule adjustments, preparation of aircraft arrangements and approval procedures were patiently proceeded. "Such robust internal cooperation was also the key to our success", says Mr. Hamada.

The most difficult part was the handling of the cargo. Since the semiconductor exposure equipment, a special cargo, is very large and heavy, not even a slightest shock can be tolerated. Furthermore, it was extremely delicate to temperature changes, so that the transport had to be carefully planned. Step by step the 3 parties closely worked together to establish the system or the procedures.

A shock detector enables to confirm impacts by changing the color inside the capsule equipped in the center when impacted by certain shock. It is used for the purpose of transport environment monitoring and to enhance awareness of the cargo handlers.

By installing shock-watch devices to detect impacts, any possible shocks are visualized, if occurred. By arranging pallets or extra-large forklifts for special cargo, safe circumstance for safe transport of the cargo without giving any shock was established.

And closest attention for the temperature changes must also be paid. Semiconductor exposure equipment has to be transported within a strict temperature range, while the time allowed to be exposed to the outside temperature is limited. Though the average minimum temperature of Tokyo in the year end is approximately 4℃, the respective temperature in the same period of east Malaysia with high temperature & humidity is about 24℃, which for sure the sudden temperature changes had to be avoided at all costs.

Therefore, a scheme was planned to enable build-up via the shortest route by parking the aircraft right in front of the warehouse. Due to the exposure time limit differs depending on the cargo, it was clearly specified in the time-line (work process) chart and thoroughly shared among all the concerned staff involved. To minimize the time of the cargo being exposed to the open air, the unloading order of the cargo from the truck was decided, eliminating exposure risks at every process. No procedures were overlooked such as adjusting the aircraft cargo compartment's temperature from 3 hours prior to departure.

Another reason making it even more difficult was that all the cargo had to be loaded on the charter flight. There were more than 40 pieces of cargo in total, each with a different size, weight, and exposure time limit. Depending on the weight of the cargo, the loadable positions on the aircraft would also be limited. While responding to the shipper's requests, to fit everything in the cargo compartment, the loading image was prepared just like a puzzle.

Mr. Hamada: "Though the deck space was just barely enough, through repeated meetings with the Professional Unit members, we came up with an idea how to load the entire cargo. I feel that my experience to be involved in the freighter aircraft operation duty after joining the company, having the opportunity to actually observe the frontline work, was an advantage to estimate the loading to a certain extent. I was also very grateful for the support from Nikon."

The entire cargo loading was successfully accomplished without a slightest mistake, based on the ANA Cargo's know-how and Mr. Hamada's skills acquired over many years. Needless to say, the success greatly owes to the support of the shipper, Nikon. Says Mr. Junichi Ishihara, Quality Assurance Department, Semiconductor Lithography Business Unit, Precision Equipment Group, Nikon Corporation;

Mr. Junichi Ishihara, Quality Assurance Department, Semiconductor Lithography Business Unit, Precision Equipment Group, Nikon Corporation

Mr. Ishihara: "For this time, Nikon side also took special measures to load the entire cargo by changing the size of the cargo packaging materials. Since it was necessary to transport all the cargo on this same charter flight, and when seeing ANA Cargo's hard work, we also wanted to somehow respond to their efforts. It was extremely difficult to reconfigure the custom-made boxes, but it was a great relief to safely load all the cargo."

The transport plan was perfectly put together without a single flaw. Upon the information of the local airport's characteristics at the destination shared by "K" Line Logistics, a solid system was put in place being well prepared for any eventuality. Finally, the day of the transport arrived.

With outstanding handling skills, we are here to meet the customers' needs

On the day of the flight, delivery/acceptance of the cargo started at 11:00 a.m., and the departure schedule from Narita to eastern Malaysian City was 18:35. Including Nikon attending the build-up of the cargo, everyone bated their breath while watching the handling.

Mr. Ishihara: "I had the special privilege of being able to observe the handling, and was extremely impressed by each process carried out very carefully, considering to eliminate all risks."

Thanks to the thorough preparations in advance, the handling proceeded smoothly. The most difficult part to load the main components of the semiconductor exposure equipment, which weighed nearly 10 tons, was conducted by "rotational loading", in which the cargo was placed vertically into the aircraft and then rotated inside the compartment.

Due to its weight of nearly 10 tons, even a slightest collision against the wall may cause a serious damage to both the cargo and the aircraft. This is a task which fully tests the competence of the handling staff's skills. Owing to the outstanding skills of the Professional Unit's members, such challenging load handling could be achieved without difficulty. Overcoming the first hurdle or barrier, everyone breathed a sigh of relief.

However, it was still too early to feel relieved. Including the handling after landing of course, anticipating possible irregularities at the local airport of the destination, the preparation for take-off was made without fail. Mr. Hamada, who boarded the same flight with the cargo, recalls as follows;

Mr. Hamada: "The loading smoothly proceeded, but still we had to be on our toes, wondering 'is the impact of landing okay?', or 'can we safely unload the cargo?'. Our only focus was to deliver the shipment safely."

Approximately 7 hours after the delivery/acceptance of the cargo, the "Boeing 777F freighter" departed for eastern Malaysian City with the hopes and thoughts of all concerned.

Beyond business partners, bonds were born by the transport project

The "Boeing 777F freighter" arrived in the eastern Malaysian City right after midnight. It was a night of poor visibility, and the aircraft was landing on an unfamiliar place. Mr. Fukami, who had flown to the destination in advance, was waiting and praying for the flight to arrive safely.

Mr. Fukami: "I had no choice but to just wait. When the aircraft appeared in the darkness after the scheduled arrival time, I was deeply moved. I truly felt it was a hero."

The aircraft with the cargo safely landed in the eastern Malaysian City. The unloading handling also proceeded smoothly, while all the shock watches installed to the shipment showed no response. It was 3:00 a.m. when all the cargo was handed over safe and sound.

Mr. Hamada: "When I met everyone involved at the site, I was so moved that tears welled up in my eyes. I was filled with relief by safely delivering the important shipment. We firmly shook our hands when parted, and I believe it was the moment when a tight bond was born beyond as mere business partners."

When both Mr. Itagaki and Mr. Ishihara of Nikon were informed of the shipment's safe arrival, they were pleased from the bottom of their heart about this time's success.

ANA Cargo's Japan Quality supports various industries globally and transports reliably

This time's project was able to be realized based on the combined efforts of ANA Cargo, Nikon, and "K" Line Logistics as trinity. The members of the 3 parties looked back on the project;

Mr. Itagaki: "Nikon's semiconductor exposure equipment is stated to be the 'most precise machine in the history'. Of course, it is as delicate as its name, but it also embodies the pride of Nikon's manufacturing. We are extremely happy and satisfied with the ANA Cargo's high-quality handling provided for such sensitive cargo transport."

Mr. Fukami: "There were many cases being our first attempt, so we faced various challenges until the transport took its shape. It was impressive to see how we proceeded towards the goal by mutually proposing multiple options to realize or respond to the requests each time or for each case. I shall take my hat off for ANA Cargo's remarkable approach, proposal capability, and flexible responses to our requests."

Mr. Hamada: "I am proud to say that our air transport is not just a service, but is a global infrastructure. Air cargo is closely connected to many industries, and the commodities handled widely range from semiconductor equipment to perishables. Consequently, we can face our duties with the pride to support many industries on a global scale, and it is the most interesting part of this job. Based on the know-how gained through this transport, ANA Cargo shall continuously make every effort to enhance the quality in the future."

Not only the successful offline charter flight transport to the eastern Malaysian City, but also this project could be perfectly completed in handling the highly sensitive semiconductor equipment. ANA Cargo and ANA Group will keep moving forward as a partner to create the new future together by flexibly responding to the valued customers' needs.

For information about ANA Cargo's solutions,

please see below.

You can find information regarding international cargo transportation.

Mr. Ryutaro Hamada

Tokyo Sales, International Cargo Sales Japan, ANA Cargo Inc.

Joined ANA Cargo Inc. in 2018. After experiencing export handling of passenger flights and B6F/B7F freighters, was assigned to the Tokyo Sales. Current hobby is exploring "ramen" (Japanese noodle) shops.

Mr. Ryohei Itagaki

Logistics Department, Procurement and Logistics Sector, Production Technology Division, Nikon Corporation

Joined Nikon Corporation in 2010. After being in charge of product duties in the Semiconductor Business Division, was assigned to the Logistics Department handling Nikon products' logistics. Current hobby is watching sports.

Mr. Junichi Ishihara

Quality Assurance Department, Semiconductor Lithography Business Unit, Precision Equipment Group, Nikon Corporation

Joined Nikon Corporation in 1984. After gaining experience in the semiconductor exposure equipment manufacturing division, was assigned to the Quality Assurance Department. Current hobby is leisure cycling (= "Yuru-Pota" in Japanese) on a road bike.

Mr. Takateru Fukami

Semiconductor Sales Section, Project Cargo Department, "K" Line Logistics, Ltd.

Joined "K" Line Logistics, Ltd. in 2008. After working in the customs clearance and the CS department at Narita Airport, experienced sales and human resources at the head office, and is currently assigned to the Semiconductor Sales, Project Department. Current hobby is watching sports.

Other CARGO+

-

Departure

Departure

Deepening the bonds of human and panda by cross-border. Transporting 3 giant pandas to China based on 3 parties’ cooperation.

-

To the Bright Future

To the Bright Future

Pharmaceuticals = Novel Coronavirus Vaccine by Air Transport Delivering Promising Life and Better Future.

-

BLUE JAY

BLUE JAY

Large cargo “Boeing 777 Frey”. Supported by the “Tar Machine”. The aviation logistics business’s future.

-

Delivery

Delivery

Bringing Japan’s Quality to the World. The Professional Unit tackles special cargo transport challenges in vaccines, semiconductors, and animals.